Timor - Grand Duke Mine

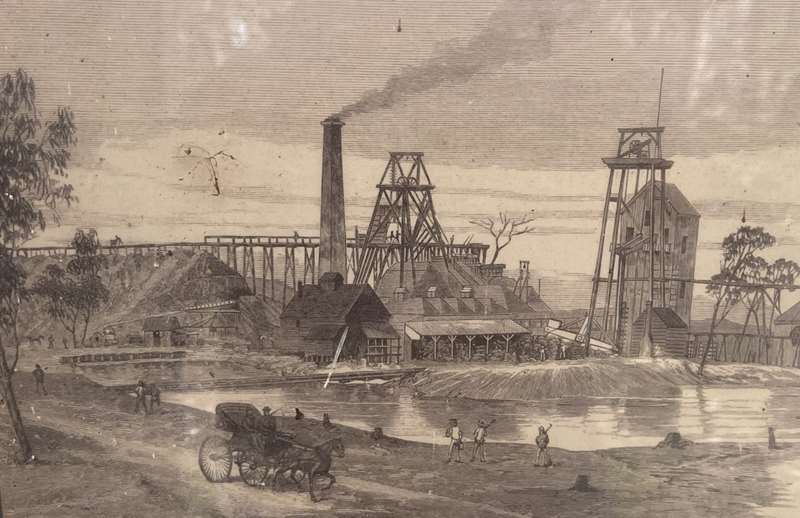

One of the State's richest deep alluvial gold leads was discovered running through Timor. Mining on this lead was dominated by the Duke and Timor Gold Mining Company (later known as Duchess of Timor, 'Duke', and Grand Duke). After experiencing great difficulty in sinking through unstable and very wet ground, the company imported from England a massive Cornish pumping engine which was the most massive in the State.

The Duke and Timor Deep Lead Gold Mine is the most prestigious mine of Maryborough's extensive deep lead goldfield and one of the State's most successful deep lead mining operations. The property alone produced almost one quarter of the 4,000,000 pounds worth of gold estimated to have come from the Maryborough deep leads.

The site has a huge stone arch which are the remains of the mine's massive Cornish pump house. It is surrounded by mullock heaps and filled mine shafts.

Access to the site - The site is reached via Grand Duke Mine Road which can be muddy and potholed when it is wet. If using a two wheel drive vehicle under these conditions, you can park at Bet Bet Creek Road and take the short walk (about 200m) to the mine.

The information signs at the site have the following information:

History of Grand Duke

Running through this reserve was one of Victoria's richest gold deep leads. From 1869 to 1896 this mine produced 216,000 ounces of gold, valued at over 885,000 pounds.

The Timor area was mainly mined by the Duke and Timor Gold Mining Company, later known as Duchess of Timor, Duke, and Grand Duke.

On 3 May 1869, at a traditional afternoon ceremony, the machinery was started and launched by the old process of 'giving it a name'. A baptismal ceremony was performed, with a Miss Eliza Watson dashing a bottle of champagne over the fly wheel on its first revolution and proclaiming its name to be 'The Galatea'.

The mine here was renowned for the massive pumping engine it boasted. Imported from England, the massive Cornish pump was an improvement that was added in 1874. It had a 30 ton iron beam.

The mine was the economic centre of this area, employing hundreds of men over its 27 years. At the height of its operation the company's proprietors boasted that nearly all the inhabitants of the nearby towns of Timor and Bowenvale depended on the mine for support.

There were some tumultuous times at the mine, with periods of financial strife as well as accidents. When the pumps broke down in 1879 the mine flooded and remained out of action for two years.

Mining was a dangerous occupation and a tragic accident in December 1883 claimed the lives of four men.

As the ground here was so wet, pumping water out of the mine was crucial to safely reach the gold. It was this pumping engine, reported to be the largest of its kind in Australia, and comparable in size to just two others in the world, that was the key to the success of the Grand Duke mine. Many other smaller nearby mines also had their water pumped out.

During the last seven years of the mine's operation it pumped out 2,000 gallons of water every minute, making this the longest and most continuous wet mine in the state.

As well as the pump house and engine, there were four main shafts, 12 Cornish flue boilers, eight iron puddling machines and one battery of 20 heads.

A Massive Pumping Engine

The arch before you is all that remains of the pump house that served to remove water from this mine.

When mining started at Timor in the late 1860's the ground here was very wet. If miners were to have any success in reaching the gold they had to remove the water from the ground.

To deal with this challenge the company imported a massive Cornish pumping engine from England to pump water out of the mine. It was reputed to be one of the best pumping engines in the world at the time. The engine generated 270 horsepower and its iron beam, weighing 30 tons, was the largest in Victoria. The beam of the large pumping engine see-sawed on this pump house wall to move the plunger or bucket in the pump up and down.

The vertical cylinder was 80 inches in diameter with a stroke of 10 feet. The piston itself was eight inches in diameter and 17 feet high and the piston pump had a diameter of 22 inches. For such large engines a massive wall to support the beam was necessary. The piston operated on the downstroke and consequently the cylinder had to be anchored to a considerable foundation to overcome the weight of the pump rods in the shaft. The whole apparatus had to be contained in a tall building because of its vertical configuration.

The pumping engine's building has beam walls six feet wide and over 26 feet long which rest on foundations 16 feet deep. The granite used to construct the arch was quarried at Mt Hooghly, some eight or nine kilometres away.

An Underground World

For many years miners worked beneath the arch in front of you.

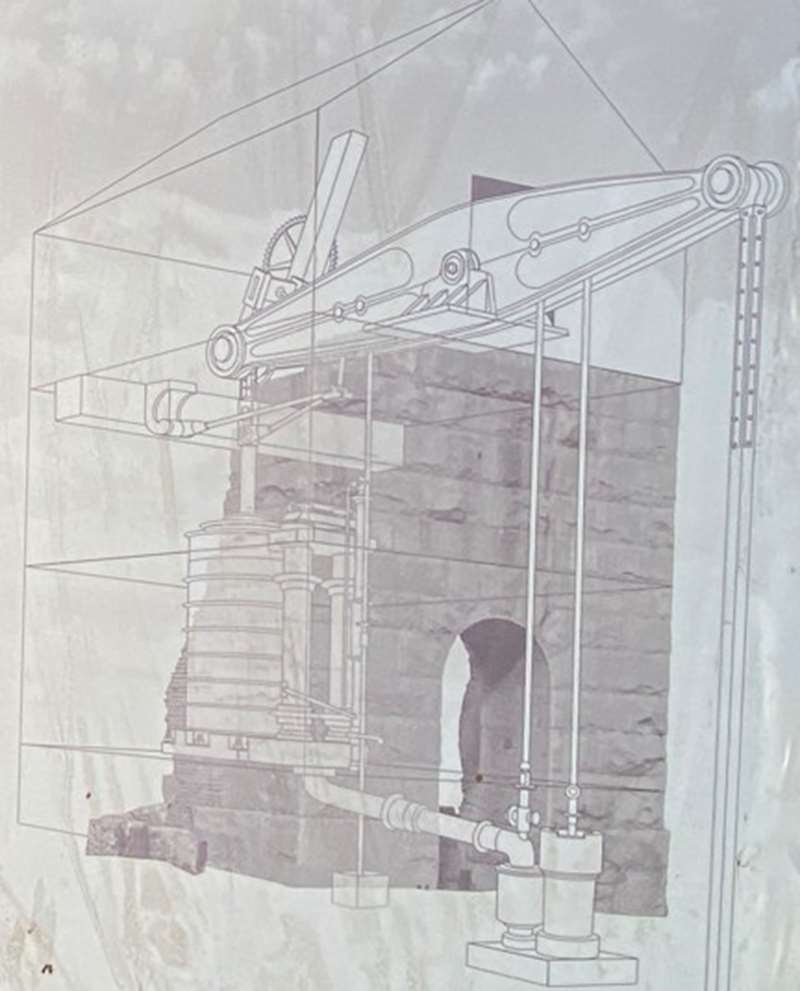

The effort the men who created this mine went to all those years ago almost defies imagination in todays electronic, hi-tech world. This diagram shows what lay beneath the ground when the mine was operating.

Two shafts with pump rods connected by a system of rods and bobs worked in unison to raise the water up out of the main shaft and other connected mine tunnels and shafts in the area.

Once in operation the pump raised an incredible 200 gallons of water each stroke which equated to 2,000 gallons each minute and over 20 million gallons each week. By removing this water the miners could then continue their mining to remove the gold from the rich lead that extended about four miles underground from here.

Grand Duke Historic Reserve

Mining Methods

A range of mining methods were used over the years at this mine. Wherever possible, miners dug upwards not downwards. Shafts were sunk down, but then it was usual to mine upwards as it was much easier. The mined material fell to the floor level and was easily loaded into skips. Mining upwards to take out the ore body is known as 'stoping'.

As quartz was removed giant cavities were created underground. This meant that the roof of the tunnel needed to be supported. The land around this and any major mine was usually cleared to satisfy the mine's need for timber to create posts and rails to provide this support, as well as sleepers and fuel for mine steam engines.

To remove gold from the local gravelly clay miners mixed this clay gravel with water. The mixture was stirred and stirred as more water was added, allowing the heavy gold particles to sink down in the soupy sludge. This process was known as puddling.

The Forests

By the early 1870s the impact of mining on the surrounding forests was evident. The massive demand of the deep lead mines for timber, both for underground use and as fuel for the boilers, had taken a devastating toll. This mine alone used hundreds of tons of firewood each week to keep the boilers going. The average number of trees left in forests around Maryborough and Bet Bet in the late 1800s was 'only three old twisted trees and fifteen young trees to the acre'. Despite the rapid rate of deforestation it was not until the turn of the century that Maryborough forests were closed as a source of timber for mining.

Mine Closure

The mine worked successfully until December 1895 when the company decided to close the mine and the manager was instructed to cease pumping. Preparations were made and despite the intervention of the Minister for Mines, arrangements to keep the pumps open could not be negotiated because other mines were unwilling (and Grand Duke unable) to finance the running. The company purchased another lease, dismantled and removed all the equipment. In March 1896 the Inspector of Mines reported that the water was rising 3 1/4 inches (8.5 cm) per day. On October 14th 1896 the Grand Duke lease was declared void.

Review:

The huge stone arch of the Cornish pump house is an iconic sight. The area has lots of mullock heaps which can be climbed for nice views across the site. The easiest way to get to the top is from the west side. There is one picnic table and information boards.

Photos:

Location

Grand Duke Mine Road, Timor 3465 Map

Web Links

→ Duke and Timor Deep Lead Gold Mine (Victorian Heritage Database)