Stawell Gold Mine

Stawell Gold Mines has operated at its current location since 1981, which has involved the progressive mining of gold in a series of open pits and extensive underground workings. The surface operations are situated adjacent to the eastern boundary of the Stawell Township and encompass an approximate area of 380 ha. The site's underground workings extend from the Magdala portal in a north-westerly direction underneath the town.

Stawell Gold Mine is capable of processing approximately 850,000 tonnes of ore per year. The processing plant is a conventional gravity/leaching recovers gold process which from both underground (sulphide) and surface (oxide) ore sources. Processing involves a two-stage crushing, milling and a Carbon in Leach (CIL) circuit. Most ore types require further liberation of the gold from sulphide materials. This is achieved in a two-stage floatation circuit where gold-bearing sulphides (e.g. pyrite, arsenopyrite and some phyrrhotite) are concentrated. The ground sulphides and flotation tail are then recombined and sent to the CIL circuit, where sodium cyanide is used to leach the gold from the slurry.

At the mine site there is a visitor observation point where you can observe the functioning mine including the processing plant and find out interesting information (suitable for both adults and children) about mining. Within view there is a tunnel going underground where you might be lucky enough to see a giant rock truck. There are also some specimens showing the different type of rocks in the mine and a rock drill.

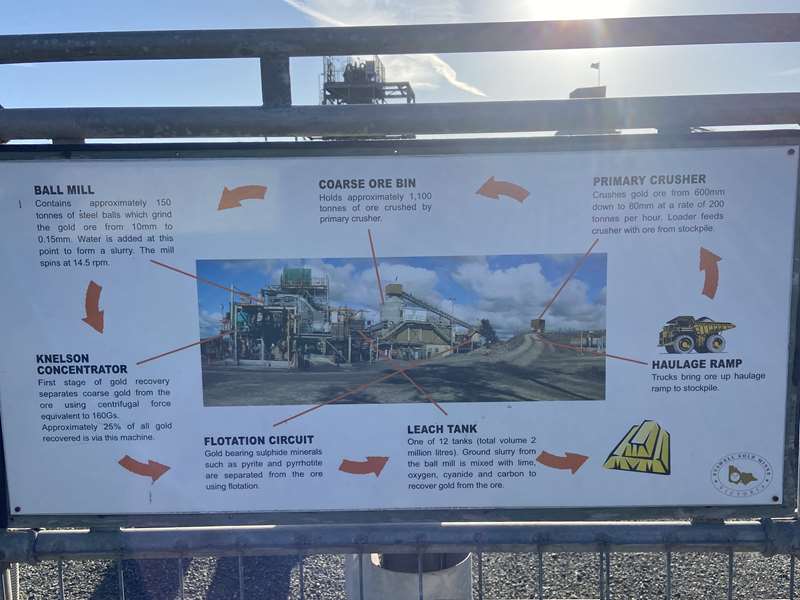

You can see the elements of the gold processing operation including:

- HAULAGE RAMP Trucks bring ore up haulage ramp to stockpile.

- PRIMARY CRUSHER Crushes gold ore from 600mm down to 80mm at a rate of 200 tonnes per hour. Loader feeds crusher with ore from stockpile.

- COARSE ORE BIN Holds approximately 1,100 tonnes of ore crushed by primary crusher.

- BALL MILL Contains approximately 150 tonnes of keel balls which grind the gold ore from 10mm to 0.15mm. Water is added at this point to form a slurry. The mill spins at 14.5 rpm.

- KNELSON CONCENTRATOR First stage of gold recovery separates coarse gold from the ore using centrifugal force equivalent to 160Gs. Approximately 25% of all gold recovered is via this machine.

- FLOTATION CIRCUIT Gold bearing sulphide minerals such as pyrite and pyrrhotite are separated from the ore using flotation.

- LEACH TANK One of 12 tanks (total volume 2 million litres). Ground slurry from the ball mill is mixed with lime, oxygen, cyanide and carbon to recover gold from the ore.

The Stawell Underground Physics Laboratory (SUPL) officially opened in August 2022. SUPL is 1km straight down, just behind Moonlight Street. By going underground, we are shielded from much of the cosmic radiation we experience on the surface of the Earth. Cosmic rays are high-energy particles that cannot readily pass through rock, so by going underground, we remove much of the background noise that these particles produce in scientific experiments. This makes SUPL perfect for extreme precision measurement experiments where the most non-reactive particles are being investigated, including dark matter particles.

The mine is only 1.2km from Big Hill lookout along Reef Road.

Location

43 Reefs Road, Stawell 3380 View Map

✆ (03) 5358 1022

Email Enquiry

Web Links

→ stawellgoldminescommunityhub.com.au

→ Stawell Gold Mines on Facebook

→ Stawell Underground Physics Laboratory on Facebook