Maldon - The North British Mine

The remains of the North British Mine can be seen on Parkin's Reef Road.

THE GOLD RUSHES

Maldon is one of a group of Victorian towns that was born with the great alluvial gold rushes of the 1850's and survived beyond the golden decade, through the exploitation of quartz reef gold. Alluvial gold was first discovered in Maldon in late 1853, followed by quartz reef gold in December 1854. Parkins Reef was first opened in 1857. Until the early 1870s quartz and alluvial mining employed roughly equal numbers of miners. After the mid 1870s reef mining took over as the major employer of labour in Maldon.

Initially quartz reefs were easily worked by individual miners. However, by the late 1850s miners were battling unsuccessfully with the heavy costs of sinking shafts, hauling and crushing quartz and bailing water. To raise the capital needed to overcome these problems miners were forced to amalgamate their small claims and float them as public companies.

One of these early companies was the Parkin's Reef Quartz Mining Association, formed in 1860. However, poor gold yields in the early 1860's discouraged shareholders and by 1864 the Association had failed for want of capital. The claim was then purchased by James Ward, John Robinson and Robert Dent Oswald, and worked as partnership. Within a year Oswald had bought out his comrades, and in September he registered the lease as the North British Quartz Mining and crushing Company.

There is an interesting and informative description of quartz mining at the entrance area to the mine remains.

ROBERT DENT OSWALD

In the 1880's the North British Mine was described as one of the richest in the world, and it was owned by one man - Robert Dent Oswald.

Oswald was born in 1830 at Lauriston, County Stirling, Scotland. In 1854 he emigrated to Victoria as a carpenter and briefly worked in Melbourne. Due to shortage of labour his wages were high but the lure of gold and higher rewards soon drew him to Maldon. Here he worked in small co-operative parties and when the Parkins Reef Association was formed he was appointed manager. From about 1859 he operated a small crushing works - the Caledonian, in Long Gully (along High St.). It was probably the profits from this battery that enabled him to buy out his partners. At the same time he speculated in shares and the formation of other public mining companies. In the 1860's he was able to purchase the other major mine on Parkin's Reef, and the Independent.

QUARTZ MINING AT MALDON

By 1865 three of the existing kilns at the North British were in place and capable of roasting 100 tons of quartz at a time. The burning of quartz, or calcining, was an early method of dealing with Maldon's refactory ores. By burning the quartz arsenical, iron and copper pyrites were removed. After burning in the North British kilns, the quartz was transported to the 20 head of stamps and the chilian wheel for crushing. The tailings were then treated with mercury, and the amalgam formed was smeltered to produce gold bullion.

THE NORTH BRITISH MINE

Oswald's purchase of the Parkin's Reef mines was not immediately profitable. During the 1870s Maldon's mining industry was in a depressed state. Part of this was due to "share jobbing" in the mid to late 1860s. Rather than lay aside funds for development in good years, Maldon's shareholders were paid prodigal dividends. When yields dropped numerous mines were starved of capital for development, and either suspended operations or let the mines on tribute. Employed as tributors, miners took over abandoned claims and paid the owners a share of any gold won. For most of the 1870s, the Parkin's Reef mines were let on tribute. Under this arrangement Oswald did not have to pay working expenses but stood to gain a quarter of the gold found.

In the late 1870s Oswald's fortunes changed dramatically when tributors found rich stone at the 150 foot level in the North British. With these riches, Oswald set about refurbishing the North British. In 1877 a head frame was erected above the shaft and a steam winder was installed. To more speedily break the rock, compressed air rock drills were introduced in the early 1880s, and in 1885 a new battery was erected. These capital works were more than adequately repaid: between 1885 and 1889, Oswald's private mines produced almost 50,000 ounces of gold.

In December 1890 disaster struck the North British Mine and its employees, when a fire destroyed the winding and pumping machinery. The chief producer in a depressed gold field, the North British employed over 100 men, or one third of Maldon's quartz miners. With little alternative employment these men were forced to accept a two month lay-off while new machinery was installed. Oswald made good use of this set back and he decided to completely refurbish his mine. In addition to replacing the machinery destroyed by the fire-winding machinery, air compressors, and boilers, he installed a chlorination plant to treat tailings. For many years Oswald had been dissatisfied with the roasting of tailings. With a large accumulation of tailings, the chlorination works promised a rich harvest of gold. However, Oswald died in November 1891 before he could realise on his investment in this new plant.

The wealth from this mine made Oswald one of the State's most renowned 'quartz kings'. Unlike other 'quartz kings' he took an active and open part in the civic life of Maldon. He served as a Justice of the Peace and as president of the Shire of Maldon. His home 'Lauriston' can be seen in High Street, opposite the Caledonian kilns, and his is buried in the Maldon Cemetery.

After Oswald's death, the trustees of his estate continued to operate the mine until 1913. It was then floated as a public company and continued employing labour until 1928. The mine was the second last to close in Maldon. By 1926 it had produced well over 242,000 ounces of gold.

In the early 1900's ...

"The miners started work about 7.00am for the looming shift. All over town you could hear the miners' whistles going. Then the stamping batteries would start up. Mr Stacey said it was like living near trains... it sounded strange when they stopped. Their cottage was over the road from the Oswald's mine, and when they finally stopped at 11.00pm, they would mil-) up because it was suddenly quiet,"

Interview with Toni and Bertha Stacey, Parkins Reef Road, Maldon, June 1988

Map of North British Mine Area

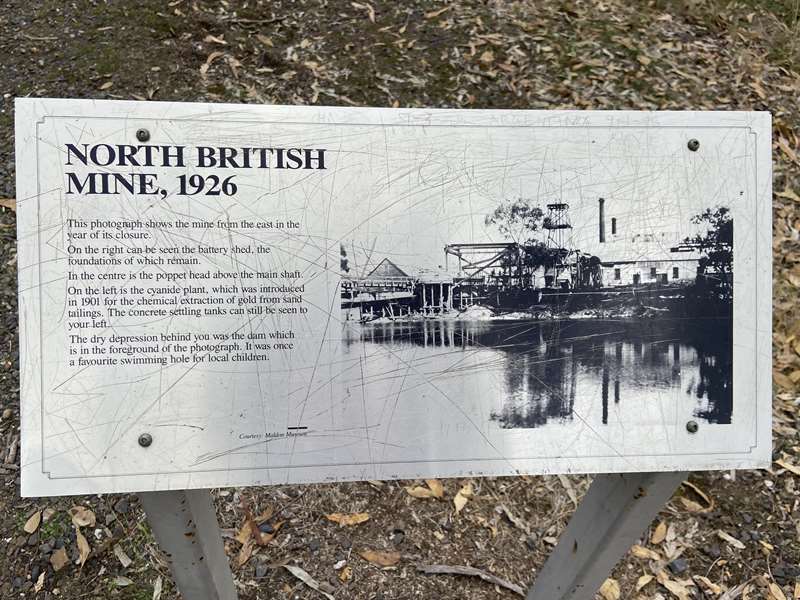

NORTH BRITISH MINE, 1926

This photograph shows the mine from the east in the year of its closure.

On the right can be seen the battery shed, the foundations of which remain.

In the centre is the poppet head above the main shaft.

On the left is the cyanide plant, which was introduced in 1901 for the chemical extraction of gold from sand tailings. The concrete settling tanks can still be seen to your left.

The dry depression behind you was the dam which is in the foreground of the photograph. It was once a favourite swimming hole for local children.

QUARTZ KILNS

Calcining (the roasting of quartz in kilns) was an early method-of preparing gold bearing rock for crushing. Impurities were burnt off, and the quartz was made more brittle.

This process was continued at Maldon until about 1900, perhaps ten years longer than at other goldfields. This was partly because of the hardness of Maldon's rock, but some said it was because of local sentiment and conservatism about the kilns.

Quartz kilns came to be seen as a feature of Maldon, and these are some of the best surviving examples in Victoria.

The three southern kilns were built in 1864 and the northern two were added later. A conspicuous break in the stonework marks their joining.

The most southerly kiln was partly destroyed in 1913 to construct a rock breaker, which was located over the concrete lined pit.

OSWALD'S FAMOUS WORKSHOPS

The path takes you between the battery and the boiler foundations to the remains of the quartz kilns and then to the shaft.

The path returns past the site of the workshop south of the winder foundations where Oswald's compressed air rock drills were manufactured. They became widely used throughout Australia.

The foundations of the air compressor, which had the capacity to provide air for twenty drills, are on your left.

A SOURCE OF LIGHT ... AND DANGER

The white chemical compound calcium carbide was used as a source of light above and below ground.

This large carbide dump was the waste from a gas-producing plant near this site. Gas was piped above ground to illuminate the mine buildings and workshops.

Miners also used carbide lamps to light their work at the rockface. The inflammable gas acetylene was produced from the reaction of calcium carbide with water. The gas gave a pure, white light but had an unpleasant garlic-like odour and was potentially explosive.

Underground work was dangerous, and many accidents occurred at the quartz mines. Terror struck the hearts of Maldon residents at the sound of prolonged mine whistling - a signal for disaster.

Review:

This is one of the best historic gold mines to explore, with well-preserved quartz kilns, machinery foundations and mine shaft. Most of the extensive ruins are fenced off for safety and protection of the heritage areas.

At the car park there are toilets, six picnic tables set in a shady area under trees, water tap and fireplace.

You can explore the mine complex along the shortish walking trail, or take the longer Parkins Reef Walking Track (2.3km return) to the south. This passes cyanide vats, sand and tailings heaps, puddling machines, dams, water races and alluvial diggings.

Photos:

Location

Parkins Reef Road, Maldon 3463 View Map